There are many printing techniques and we do it all!

Digital Printing with CMYK colors

Digital printing has enabled full-color printing on card stocks, papers and envelopes at a lower cost and quicker turnaround as there are no plates required or expensive set up fees to accomplish this type of printing. Colors are formulated by combining various amounts of Cyan, Magenta, Yellow and Black toners (CMYK). It is important to note that while darker ink colors are more opaque, lighter colors will take on the characteristic of the paper color it is printed on. For example, 100% Magenta printed on 24 KT will not look the same as 100% Magenta printed on Classic White; 100% Yellow will not show up on darker stocks like Classic Black. The lighter the stock, the more true the color. Digital printing is perfect for watercolor, hand-painted or multicolored aesthetics, photos and beautiful typography. Ink colors are calibrated specifically to each printer, so do not expect the output from your printer to be an exact match to ours. There will be variations.

Digital Printing with White Ink

Similar to digital printing with CMYK toners, white toner is fused to the surface of card stocks, papers and envelopes with heat. This digital option offers a great way to highlight white text and graphics on dark pigmented stocks with smaller quantities and quicker turnaround. Though more cost effective than foil stamping with white matte foil, digital white printing is less opaque. Your type needs to be large enough to be legible.

Thermography

Thermography is a print process that relies on heat to create raised ink, resulting in an elegant, tactile effect. In this process, a resin powder is applied to the paper, adhering to the ink. After removing the excess powder, the printed piece is heated and the mixture of powder and ink dries, forming the raised effect. Most colors are printed with colored ink and then a clear thermography powder is added. Specifically for gold and silver thermography, it is printed in gold or silver ink and then gold or silver powder is added. This process is a cost-effective way to achieve the look of texture without the added costs of plate-making. When designing for thermography printing, it is best to avoid large, solid areas of color as they may blister and crack when trimming to final size. Small or thin typography is also difficult to achieve with this print process.

Letterpress

Letterpress printing is a technique of relief printing using a printing press. Custom dies are positioned into the bed of the press and inked, then paper is pressed against it to transfer the ink, creating an elegant, tactile effect. We recommend using heavy-weight stocks to maximize the look of relief printing. Letterpress is a wonderful choice for highlighting fine details. Similar to screen printing, the more ink colors that are used the more costly this process can be, as unique dies are required per color.

Letterpressing without ink

Blind Emboss / Blind Deboss

Embossing alters the surface of paper stock or other substrates by providing a three-dimensional or raised effect on selected areas. The procedure requires the use of two dies: one that is raised and one that is recessed. The dies fit into each other so that when the paper is pressed between them, the raised die forces the stock into the recessed die and creates the embossed impression. A specific level of pressure is applied to the dies in order to squeeze the fibers of the paper, which results in a permanently raised area in the paper.

Debossing is similar to embossing, but recesses the design rather than raising it. Rather than the paper being raised in specific areas, it is indented. The process involves applying pressure to the front side of the paper and forcing the material down from the surface. Although it is not as common as embossing, it is occasionally used to provide a different effect or appearance that fits a particular theme.

Foil Stamp

Foil stamping is the application of pigment or metallic foil, often gold, silver or white, to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper. This process is a popular choice for wedding invitations as it can significantly elevate the formality of a piece. Foil stamping can be combined with embossing to create a more striking 3D image

Die Cut

Die cutting is a process to cut paper and card stock into a specific shape using a steel cutting die. It can be used to punch out a decorative shape or pattern to incorporate within a larger piece, or it can be used to create the main shape of an object by cutting the entire of sheet of paper in an distinct/designed way.

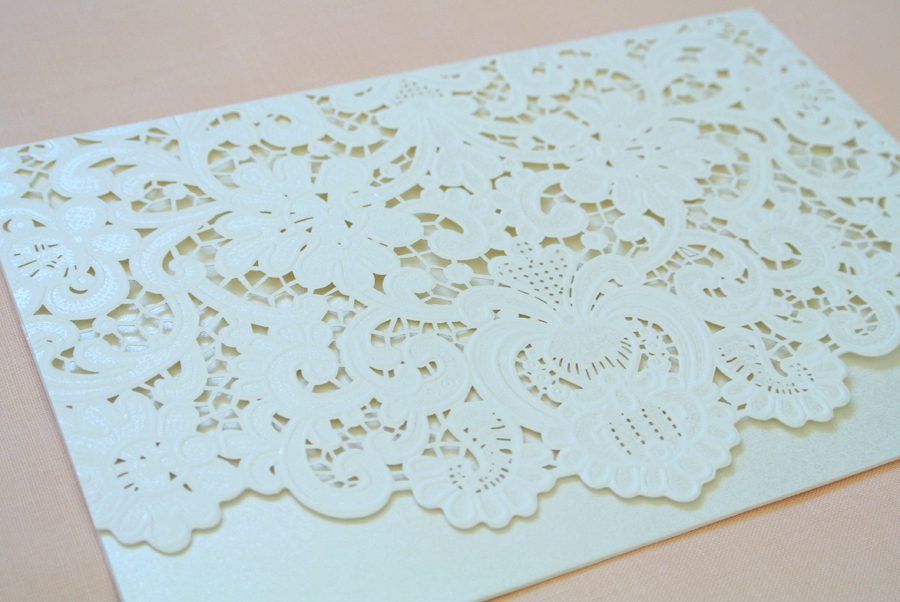

Laser Cut

A laser is used to cut precise, intricate patterns (like lace) into your paper.